Welcome to

PHU TAN CO., LTD.

Established in 2001 under the Decision No. 423 / QD-UB of July 31, 2001 of the People’s Committee of Hai Duong Province. With 20 years of formation and continuous development.

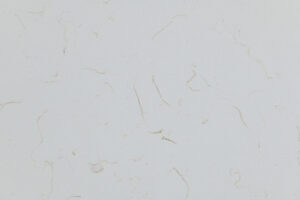

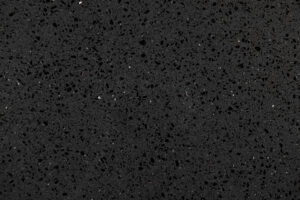

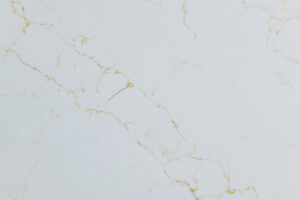

Quartz  collection

collection

view all

view all

Victown-artificial

quartz stone classic

Victown-artificial

quartz stone Natural

vicrown

CATALOGUE

NEWS

Chưa phân loại

Premium Stone Surface Collections

Where to buy premium stone surfaces? Phu Tan Stone’s (Vicrown Quartz Surfaces) artificial quartz stone...

Chưa phân loại

Tips to Keep Quartz Stone Countertops Always Clean

Keeping your home looking modern and elegant does not have to be a difficult or...

Chưa phân loại

Vicrown Quartz Slab Manufacture Process – Part IV. Calibrating and Polishing

Vicrown Quartz Slab Manufacture Process – Part IV. Calibrating and Polishing VICROWN After going through the...

Chưa phân loại

Quartz Products CARE & MAINTENANCE

Quartz Products CARE & MAINTENANCE DAILY ROUTINE Just use water, dish soap, and paper towel...

Chưa phân loại

What Is SGS Certification? Why You Should Choose Vicrown Quartz Certified by SGS

What Is SGS Certification? Why You Should Choose Vicrown Quartz Certified by SGS Quality is...

Chưa phân loại

Tips for Choosing a Beautiful, Durable, and Easy-to-Clean Bathroom Vanity Top

Tips for Choosing a Beautiful, Durable, and Easy-to-Clean Bathroom Vanity Top The bathroom is more...

Style Uncategorized

Welcome to Flatsome

Welcome to WordPress. This is your first post. Edit or delete it, then start blogging!...

5 Bình luận

Uncategorized

Just another post with A Gallery

Lorem ipsum dolor sit amet, consectetur adipiscing elit. In sed vulputate massa. Fusce ante magna,...

FAQs

Phu Tan Stone branded as Vicrown Quartz is one of the most experienced Quartz manufacturers, located in Hai Duong province. Founded in 2010 by Mr. Cao Van Ty, an entrepreneur with a passion for the building materials industry, Vicrown Quartz is the second Quartz factory owned by Mr. Ty, established after the great success of his first factory. We proudly stand as a factory with 100% Vietnamese origin. With over 10 years of experience in quartz manufacturing, currently we produce and ship-out around 40.000 Sqft of Quartz per month, mostly to the US market. Our team not only continuously strives to improve our process but also does not hesitate to update the latest in-come materials and facilities, committed to ensuring stability in quality and a diverse range of designs.

– Made in Vietnam materials, ensuring the origin of the slabs helps customers avoid any issues with US CBP (U.S. Customs and Border Protection).

– Competitive price with professional and dedicated consultant, with the desire to bring added value to our customers’ businesses.

– Premium raw materials: Cristobalite Quartz sand for higher White-level surface, Imported glass materials for free-silica requirement and coloring materials sourced from Germany.

– Lasted machine imported from Keda and advantageous factory location: just 50 minutes drive from Hai Phong port.

We take pride in sharing the vision of Mr. Ty – the founder of Vicrown.

He believes that stability is the key point of a successful manufacturing business. Along with ensuring the consistent quality of slabs, Mr. Ty and his team are constantly working to innovate the production process. From the start, he was eager to import the latest machinery from Keda and recruit top Quartz experts to join his factory. His team strives to find innovative solutions to tackle quality challenges and optimize production costs.

After over a decade in the Quartz industry, he has successfully provided customers with premium Vicrown slabs, known for their stable quality and competitive pricing.

We will schedule production as soon as the customer makes a deposit for the order. It will take approximately 10 to 15 days ( longer for fabrication), depending on the design chosen by the customer. The order will then be loaded and shipped out from Hai Phong port. Shipping time will vary depending on the destination port, shipping line, and current political situation.

Yes, we do,

Our fabrication workshop has been set up since 2021 and our capacity now can reach around 15-20 containers per month. Currently we are shipping out around 5-7 containers monthly, mostly to some residential projects and prefab distributors.

. With over 3 years of experience in this field, we’re confident in our strengths: stability in materials quality, commiting project time progress, competitive pricing.

CERTIFICATE

Contact us

Thanks you and we will get back to you as soon as possible